Assembly Correction Report

Introduction

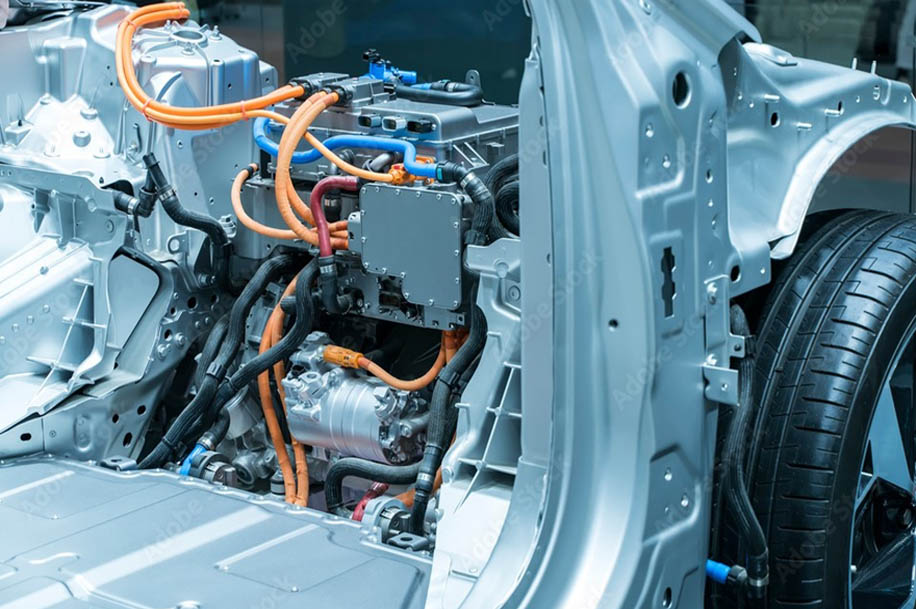

Assemblies and subassemblies are integral components of various manufacturing processes, ensuring the smooth functioning of complex machinery and products. However, even the most well-designed assemblies can encounter issues during production, which necessitates thorough checking and correction procedures.

Services

Importance of Checking Assemblies and Subassemblies

Checking assemblies and subassemblies is crucial for several reasons:

- Quality Assurance: Inspecting these components helps identify any manufacturing defects or inconsistencies, ensuring that the final product meets the required standards.

- Safety Compliance: Thorough checks guarantee that the assemblies and subassemblies comply with safety regulations, reducing the risk of malfunctions or accidents.

- Operational Efficiency: By verifying the correct alignment and functionality of these components, potential issues that may hinder the performance of the final product can be detected and rectified early on.

Importance of Checking Assemblies and Subassemblies

Checking assemblies and subassemblies is crucial for several reasons:

- Quality Assurance: Inspecting these components helps identify any manufacturing defects or inconsistencies, ensuring that the final product meets the required standards.

- Safety Compliance: Thorough checks guarantee that the assemblies and subassemblies comply with safety regulations, reducing the risk of malfunctions or accidents.

- Operational Efficiency: By verifying the correct alignment and functionality of these components, potential issues that may hinder the performance of the final product can be detected and rectified early on.

Common Problems Encountered

During the checking process, various issues can be identified in assemblies and subassemblies:

- Misalignment: Parts not correctly positioned or fitted together can lead to functionality problems and increased wear and tear.

- Defective Components: Substandard or faulty parts can negatively impact the performance and longevity of the product.

- Incomplete Assemblies: Missing or improperly installed components can result in non-functional or inefficient products.

- Interference or Binding: Parts that impede each other’s movement or cause friction can affect the overall operation and lifespan of the assembly.

Corrective Measures

To address the problems mentioned above and ensure the highest quality output, the following corrective measures can be implemented:

- Visual Inspection: A thorough visual examination of assemblies and subassemblies can help identify obvious defects or misalignments, enabling prompt corrections.

- Dimensional Testing: Conducting inspection at assembly stage and subassembly stage to ensure that the assemblies and subassemblies operate as intended, detecting any quality issues or malfunctions.

- Quality Control Checks: Regular quality control checks throughout the production cycle can help identify and correct potential problems before they escalate.

Checking and correcting assemblies and subassemblies is a critical aspect of manufacturing processes. By performing thorough inspections and implementing effective corrective measures, we can enhance product quality, comply with safety standards, and improve overall operational efficiency. Emphasizing the importance of precision, quality control, and continuous improvement will result in superior assemblies and subassemblies, ultimately leading to customer satisfaction and business success.